- #One line drawing engineering how to

- #One line drawing engineering update

- #One line drawing engineering manual

- #One line drawing engineering series

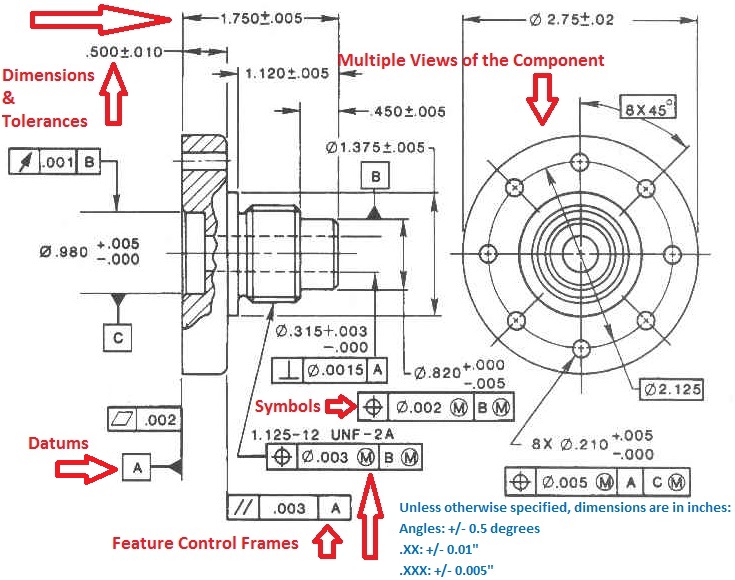

Just noting “press-fit M4 dowel” does not give material information or machine shop dowel length. In a case where hardware installation is needed, the supplier and part number should be provided on the drawing. This is especially important if you’re installing off-the-shelf hardware yourself. Also, you can provide part numbers for your machinists to look up. If the production involves the machining of an entire assembly, you should include an assembly instruction in your engineering drawing. Tip 4: Communicate Assembly Intent of Crucial Features For example, “5X 10-38 TAP” means that there are 5 10-38 threaded holes in that view. This means that the feature exists in the view X number of times. You can then label the dimension as “#X DIM”. If there are multiples of the same feature in a view, give a dimension of only one of those features.

#One line drawing engineering update

The 3D models will make it a lot easier to update drawings for revisions.Īfter you make great engineering drawings that show your special requirements, you can upload them to the RapidDirect platform that provides professional prototyping manufacturing services. The CAD program generates views with just a few clicks. Then, you can create your drawings from there.Īll you need to do, basically, is to include the dimension. However, the easier option will be first to make a 3D model. You can use CAD to make drawings from scratch.

#One line drawing engineering manual

This software comes with several advantages over manual drawings. The advent of computer-aided design (CAD) software has made things a lot easier. Handmade drawings would just make this more cumbersome for engineers. Thus, they can easily produce a cutting program as required.

This is because most CNC systems today can read the information right from the files. While these instruments are still available today for manual drawings, such drawings are not suitable for contemporary manufacturing. In past years, all that was available were drawing boards, papers, rulers, calipers, and others. Therefore, an engineer can start the manufacturing process immediately after he gets the drawing. The information may include dimensions, part numbers and names, variations, tolerances, and more. The Purpose of an Engineering DrawingĪs already mentions, this mechanical drawing includes every piece of information needed for manufacturing components. All of these are aimed at getting the products to meet requirements.

#One line drawing engineering series

The drawings also include a series of projections that show various angles of the components. The drawings can be of various forms, ranging from oblique to isometric. Such descriptions may also include specifications of acceptable variations, limits, materials, and others. Rather, its intention is to describe the shapes and sizes of components. Engineering drawing is not just an illustration. It may also provide records of already existing components. Thus, it conveys engineering ideas for a design process. The mechanical drawing includes a description of the manufacturing process. This will ensure that manufacturers can produce parts that meet specific needs. Basically, this type of drawing aims at clearly capturing all the geometric features of products and their components. What is Engineering Drawing?Īn engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical drawings, which helps to define engineering products’ requirements. Thus, you will save yourself some time and money. This ensures that you can communicate your unique ideas and requirements clearly.

#One line drawing engineering how to

That way, you can learn how to create engineering drawings effectively. We’ll also give you 8 important tips for creating better engineering drawings. This guide seeks to put you through technical drawing basics. Thus, there may be substandard formatting and negative impacts on costs, lead time, and specification clarity. This can create challenges for manufacturers who may not easily understand the drawings. However, not all engineers are comprehensively trained to create clear drawings. Most rapid prototyping customers upload design files and drawings for a better understanding of requirements. This will allow you to communicate the intent of your design for CNC machined parts. Understanding the basics of engineering drawing is a great first step. This is even truer for engineers and machinists. Drawings and pictures are among the best means of communicating one’s ideas and views.

0 kommentar(er)

0 kommentar(er)